Our Sustainable Decorations

Groupe Pochet is committed to proposing sustainable designs to its clients, in order to reduce the carbon footprint of their products.

REDUCING AT THE SOURCE: INNOVATIVE SOLUTIONS

The Pochet Group is working to reduce its environmental footprint during the decoration process, in particular by cutting emissions of Volatile Organic Compounds (VOCs) released during the varnishing process and by eliminating chrome and nickel from the galvanization process.

REDUCTION OF VOLATILE ORGANIC COMPOUNDS (VOC)

Our decorating activity is a source of significant emissions of Volatile Organic Compounds (VOCs). These are due to the evaporation of solvents during our varnishing process.

Pochet du Courval’s Gamaches and Beaugency sites have been working with water-soluble varnishes for several years. What makes them special? The solvent part is replaced by water thus avoiding VOC emissions. Today, more than 98% of the items on the Pochet du Courval sites are made with water-based varnish. For plastic articles, reducing at the source involves switching to high-solids lacquers.

The proportion of solvent is thus lowered in favor of dry matter thereby reducing the VOCs released into the atmosphere. In this way, we avoid emitting Volatile Organic Compounds during our varnishing and metallization operations on plastic parts.

PROCESSING OF VOLATILE ORGANIC COMPOUNDS (VOCS)

In order to reduce our VOC emissions, within Solev, the Group set up the Decoration Division, a unit for processing emissions at the chimney outlet. Thus, at the exit of the varnishing booth, the emissions are collected and treated in order to avoid releasing pollutants into the atmosphere.

The Solev site implemented this type of innovative VOC processing system. This enabled the site to reduce its emissions to well below the regulatory threshold in 2020.

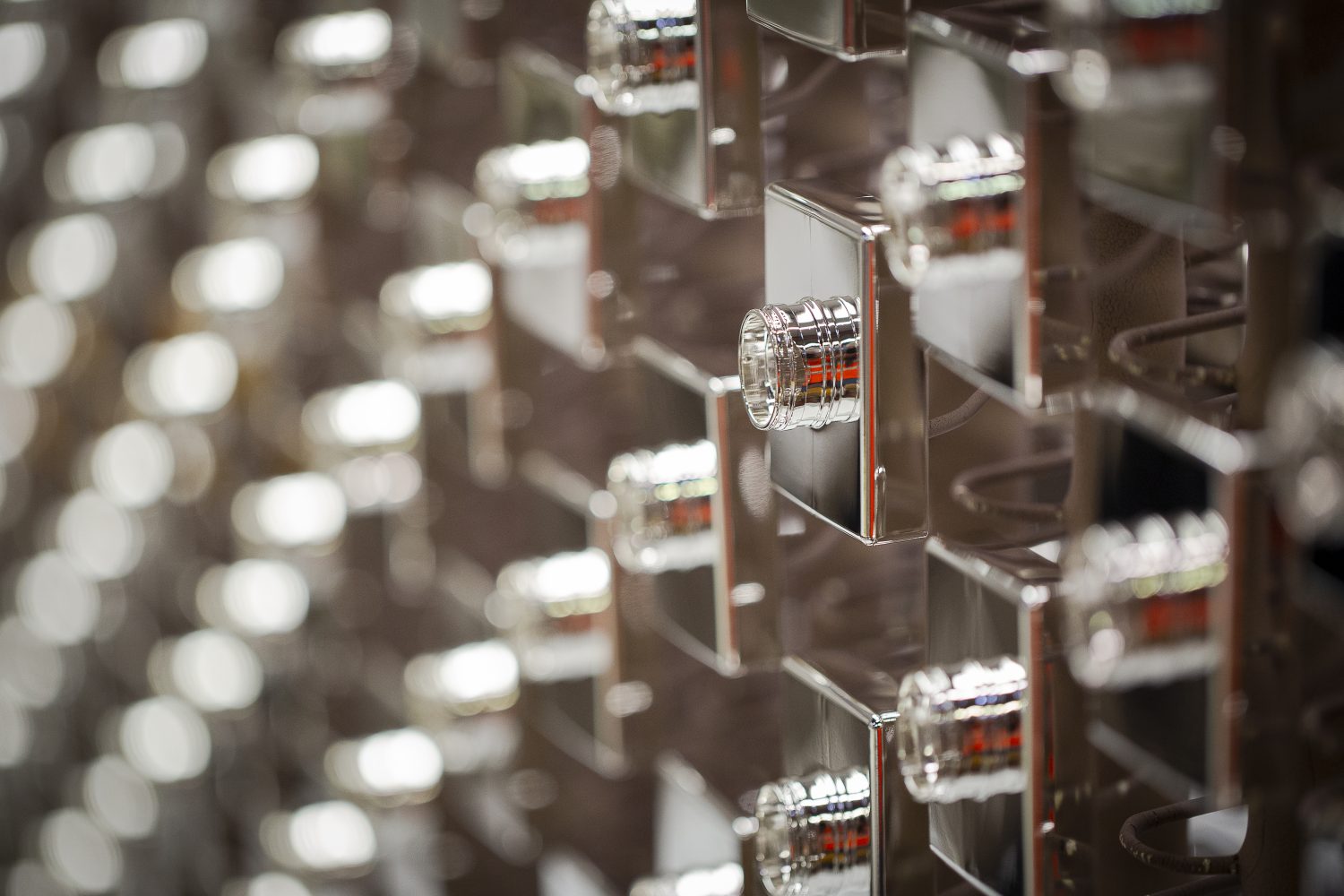

CLEAN GALVANIZATION: CHROME AND NICKEL FREE

Electroplating is a technique enabling the coating of a plastic part with decorative metallic layers.

Pioneers in pulse electroplating, Qualipac is innovating again, this time for more responsible metal decorations: in 2018, an unprecedented galvanizing line, enabling to reduce the environmental impact, was opened in Aurillac. This enables reducing the environmental impact and increasing energy efficiency: -20% less water consumption per square centimeter, more than 50% less gas consumption due to heat recovery, and more than 10% less waste. The nickel and chromium concentrations in the waste are now 20 times lower and the process no longer uses hexavalent chromium.

With a modern, safer, and more accessible facility, and with a reduced use of chemicals, we also improve the safety and working conditions of our employees.